From virtual design to physical build

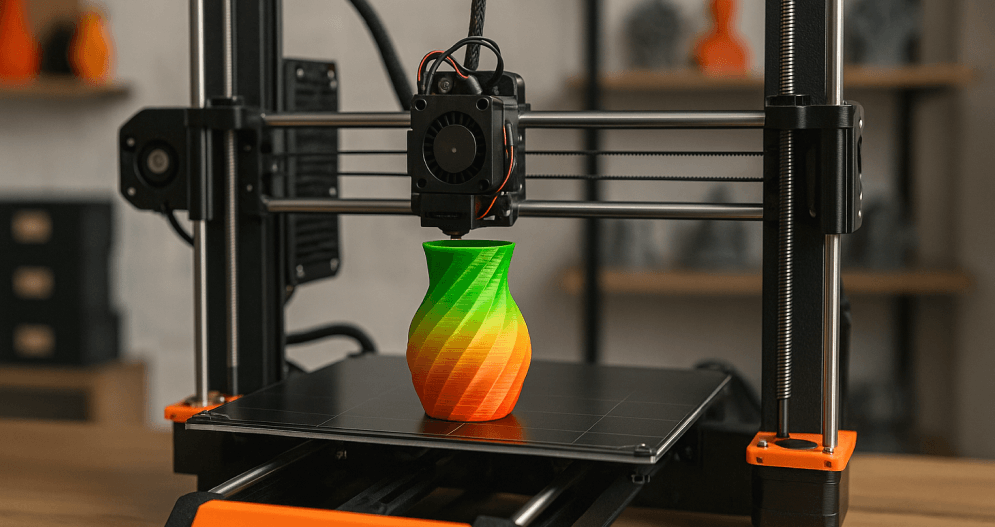

The world of design has changed forever. What once stayed locked in a digital file can now become a physical object you can hold in your hand. Thanks to a 3D printer 3D printed models move from imagination to reality in just a few hours. RealityMAX makes this process seamless by letting you create, edit, and save your 3D scenes in multiple file formats — GBL, OBJ, PLY, STL, and USDZ — so you can print them directly on your preferred printer. Whether you’re working with plastic, experimenting with new materials, or preparing engineering parts, the path from idea to product is now clearer than ever.

Why 3D printer 3D printed matters for creators

A 3D printer is more than a machine; it’s a tool for creativity and innovation. Artists can turn their digital artwork into physical sculptures. Engineers can prototype parts for testing before mass production. Small businesses can design unique products without the overhead of traditional manufacturing. Even hobby users at home can print things they love, from models to functional tools.

The beauty of 3D printed design lies in its flexibility. You can continue refining your model digitally, then reprint updated versions without wasting materials. With platforms like RealityMAX, saving and exporting files is straightforward, making the jump from screen to object feel natural.

Saving files for print

RealityMAX already includes the functionality to save your scenes in the most common 3D formats:

- STL: The standard for 3D printing, widely supported by affordable printers like the Original Prusa.

- OBJ and PLY: Ideal for detailed models and textured designs.

- GLB: Compact, web-friendly format that can be shared or printed.

- USDZ: Perfect for AR previews and Apple devices, while also compatible with other technologies.

This flexibility means you don’t need to juggle between different tools just to prepare a printable file. Once your design feels ready, simply select the right format, export, and start printing.

New materials and new possibilities

The evolution of 3D printing is closely tied to the growth of materials. What started with basic plastic filaments has expanded into a world of options: resin for high detail, metal powders for engineering, and even biodegradable filaments for sustainable builds. Businesses are exploring composite blends that mimic wood or stone, while engineers test high-strength polymers for durable parts.

For designers using RealityMAX, this means that the same digital file can take on multiple lives depending on the chosen material. A single model can be printed as a light prototype in plastic, then reprinted in stronger materials for production testing.

How businesses are using 3D printed products

Across industries, 3D printer adoption continues to grow. In fashion, teams experiment with accessories that feel futuristic yet affordable. In architecture, models are created to help clients understand complex projects. Automotive and engineering firms build small parts to review functionality before investing in larger-scale production.

Small businesses and startups particularly love 3D printing because it removes barriers. You no longer need to find a factory to bring your idea to life. A great product can start from a small home studio, powered by creativity and an affordable printer.

The human side of 3D printing

Behind every 3D printed object is a human story — a team that wanted to try something new, a founder who started small, or a hobbyist who simply loves building. Blogs and news sites are full of reviews, tutorials, and stories of how everyday people use their printers to create things that matter.

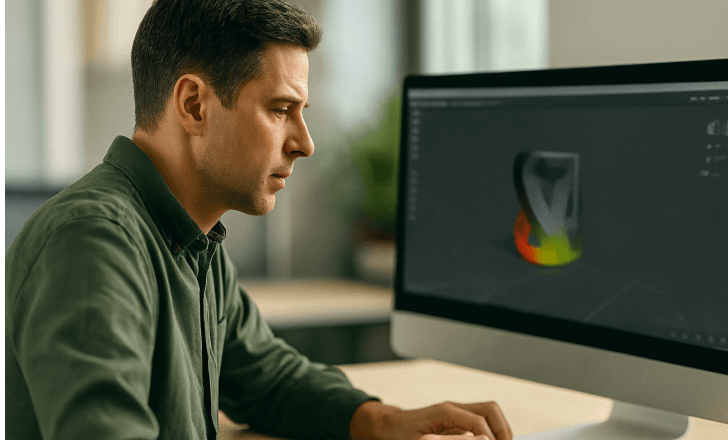

RealityMAX adds another layer to this human creativity. Instead of focusing only on the printer, it gives people a space to design, collaborate, and prepare their files together. By the time the object reaches the printer, the design has already been shaped by a mix of engineering precision and artistic vision.

What makes a print successful?

Not every print works the first time. Quality comes from understanding materials, selecting the right file format, and designing with the printer’s limits in mind. With RealityMAX, you can review your scene, save versions, and continue testing until you feel confident. That ability to adjust directly in the digital stage saves both time and resources once you start printing.

A lot of success also comes from community knowledge. Whether you read a review, subscribe to a blog, or follow a site dedicated to printables, you’ll find that the 3D printing world thrives on sharing. By learning from others and sharing your own builds, you improve not just your prints but also the broader community.

What role will 3D printing play in the future?

The innovation around 3D printing shows no signs of slowing. Businesses are experimenting with new materials, hobbyists are finding affordable ways to build at home, and entire industries are shifting toward on-demand production. For creators, this means fewer limits and more chances to bring ideas into the physical world.

RealityMAX will continue to serve as a bridge between imagination and build — a place where digital design meets real-world output. With its ability to save in all major file formats, collaborate with teams, and preview models in AR, it positions itself not just as a 3D tool but as a complete ecosystem for anyone who wants to design and print.

How can you get started with 3D printed design today?

If you’ve ever wanted to turn your ideas into physical objects, now is the time to explore. Start small with a simple model, print it in plastic, and understand how your design feels in hand. Use RealityMAX to refine your digital file, save it in the right format, and continue until you’re satisfied.

3D printing may feel like a hobby at first, but for many it grows into a business, a passion, or even a new career. The key is to start, experiment, and keep creating. In a world where digital and physical continue to merge, having a 3D printer at home or in your studio unlocks a lot of opportunities to build, design, and innovate.