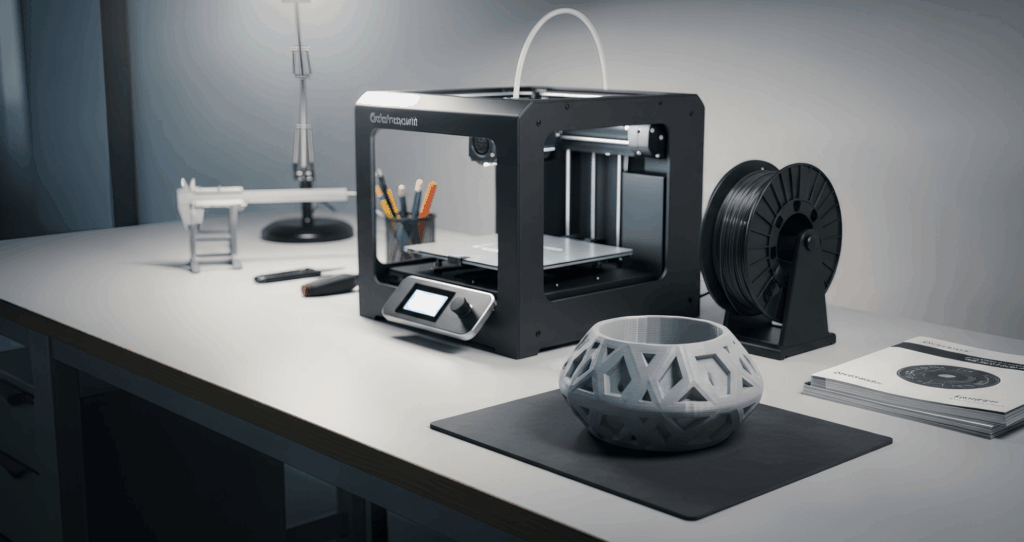

A 3D printing file is more than a container for geometry. It is the technical language that allows a printer to understand shape, proportion, structure, and the physical intent behind a digital model. Every object produced through additive manufacturing begins as a digital file, and the quality of that file determines how well the final product emerges from the printer. When people talk about successful fabrication, they often focus on materials, machines, temperatures, or slicing settings, yet the 3D printing file sits quietly at the center of it all, shaping the possibilities long before the first layer forms. RealityMAX helps simplify the visual and collaborative side of this process, giving users a place to examine models, share them with teams, and refine them before moving into production. Understanding the role and structure of a 3D printing file is the foundation for better projects, better results, and a smoother path from idea to object.

A 3D printing file carries instructions for a wide range of technologies. It supports additive manufacturing processes like binder jetting or fused filament deposition, works with CNC machining workflows that rely on clean geometry, and functions as the input for laser cutting systems that interpret contours to guide precision operations. Regardless of the device, the file must capture the surface geometry in a way that machines can understand. Without a clean, optimized, and compatible 3D printing file, even advanced machinery struggles. That is why designers, engineers, hobbyists, and manufacturers all rely on a set of well established, universally supported formats to move their ideas into the physical world. These files help machines interpret instructions and help teams communicate visually while keeping the entire process efficient and predictable.

What makes a 3D printing file different from other digital 3D formats?

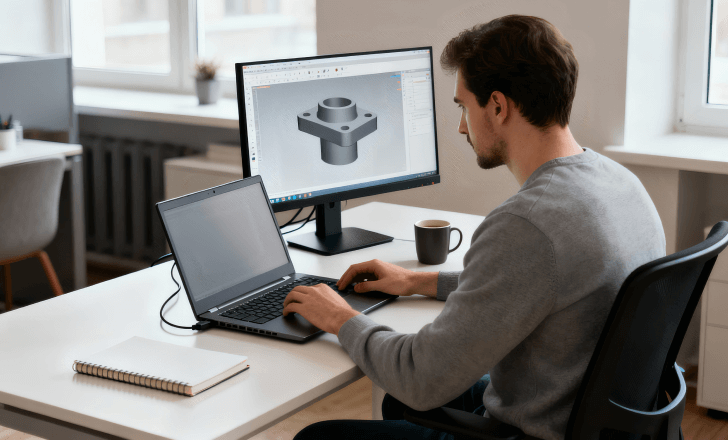

A typical 3D model can contain lights, cameras, rigging, animation curves, scene metadata, and textures. These elements matter for rendering or animation but not for printing. A 3D printing file must focus exclusively on surface geometry and the boundaries that define the shape. If the geometry contains holes, reversed normals, overlapping faces, or non manifold regions, the machine cannot interpret the instructions correctly. The printer does not see a character, a product, or a sculpture. It sees coordinates in space and instructions that must convert those coordinates into layers.

This is why the STL file format became the standard for so many industries. STL files contain triangle based surface approximations that represent the exact volume of an object without introducing unnecessary complexity. The printer slices these triangles into layers and prepares G code that governs the printing process. OBJ files also appear frequently in additive manufacturing workflows because they allow designers to work with texture previews before stripping those elements for fabrication. While the OBJ file format originated with Wavefront Technologies for computer graphics applications, it remains extremely useful in modern printing pipelines. The structure of these formats guides the quality of the printing process and influences the final output.

Most 3D applications allow exporting to multiple formats, but not all are suited for printing. A model created for animation might look perfect on screen but may be unsuitable for fabrication without changes. When users upload such a model to RealityMAX, they can inspect the mesh closely to identify issues and decide which format best suits their printing goals. The platform’s viewer helps uncover scale problems, thin surfaces, or structural weaknesses long before problems appear on the printer itself. Understanding the differences between creative 3D formats and production ready files is essential for anyone who wants to move confidently across devices and software.

Why is the STL file format still considered the universal standard?

The STL file format is simple, reliable, and accepted by nearly every 3D printer and slicing tool on the market. Its strength lies in its minimalism. STL files do not contain texture, color, or complex metadata. Instead, they store only triangles that represent the outer shell of the object. This simplicity reduces errors and minimizes confusion that might arise from unnecessary information. Because the STL format focuses on geometry alone, it is highly compatible with older and newer machines alike.

Another reason the STL file format remains powerful is speed. Slicers process STL files quickly because the data structure is lightweight. For designers working with complex objects or for manufacturers calculating the best price and production time, this speed matters. The efficiency of STL files also makes them ideal for large collections of 3D models stored online, where users need to browse, upload, and download quickly. The file size remains manageable even for intricate geometry, allowing teams to share files across platforms without significant delays.

In professional workflows, STL files often serve as the foundation for downstream instructions. Once processed, these files become G code that controls motors, temperatures, and material flows. Even when devices support more modern or proprietary formats, the STL format often acts as a trusted intermediate. The universal support ensures that printers in different parts of the world can interpret the same file consistently. For older machines or legacy manufacturing systems, STL compatibility is essential for bridging the gap between modern design tools and established hardware.

When is the OBJ file format the better option for creators?

OBJ files shine when designers need to visualize textures or evaluate aesthetics before printing. Although textures do not influence the printing process directly, they help people understand how the final object might look in different contexts. OBJ files can store material references, UV coordinates, and additional geometric detail. This makes the OBJ file format a popular choice for product designers who want to preview color schemes or branding before simplifying the model into a printable version.

The OBJ file format also plays an important role when users work across multiple applications. Many software tools for modeling, sculpting, or CAD export OBJ files because they preserve more information than STL files. When imported into RealityMAX, these OBJ files allow teams to analyze the geometry with a deeper visual reference. They can rotate the model, inspect texture alignment, verify proportions, and share the file with collaborators. Once the team approves the visual aspects, the OBJ file can be converted into an STL file to create a clean 3D printing file ready for additive manufacturing.

The flexibility of OBJ files extends to creative and commercial environments. Online platforms that host user generated content often support OBJ files because they display well in web based 3D viewers. For businesses that need to present 3D assets to clients, OBJ files provide a balance between visual richness and compatibility. They help communicate ideas and maintain design intent across teams, devices, and software ecosystems.

How does the printing process interpret a 3D printing file?

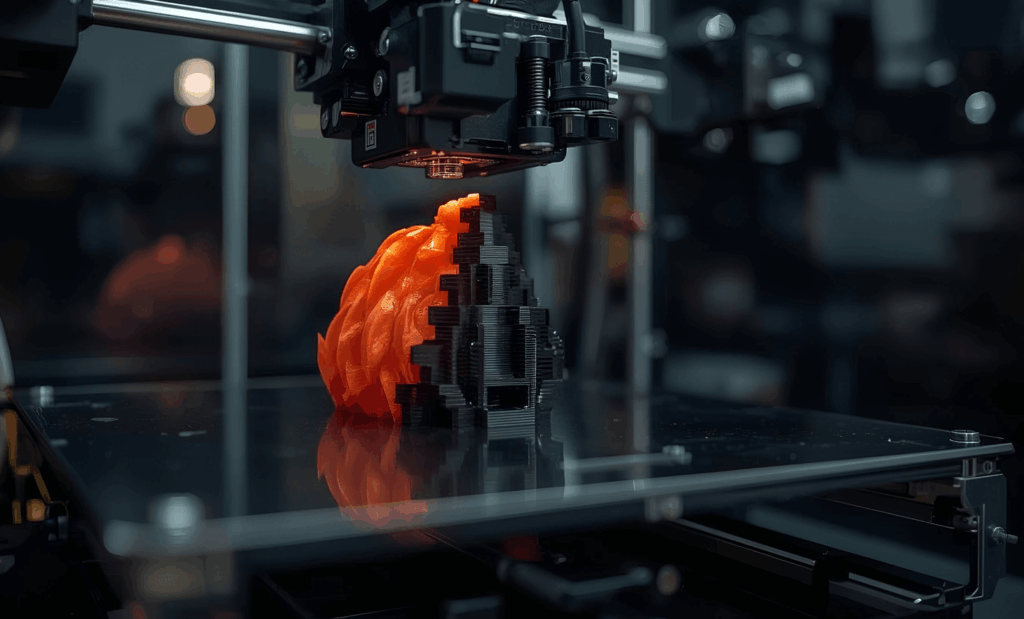

Every 3D printer transforms digital instructions into physical layers. This transformation begins with slicing software. The slicer reads the 3D printing file, identifies the outer shell and internal structures, and divides the model into horizontal layers. It determines print speed, infill density, support structures, and temperature adjustments based on the geometry. Then it generates G code, which is the sequence of commands sent to the printer.

The quality of the 3D printing file affects each step of this process. If the geometry contains gaps, the slicer may generate unpredictable toolpaths. If the file has overlapping surfaces, the printer may deposit material incorrectly, creating weak spots or aesthetic flaws. Machine specific limitations can also affect the output. For example, a printer may interpret a steep overhang differently depending on the resolution and orientation encoded in the file. Clean, optimized geometry helps machines calculate stable supports, consistent extrusion, and accurate form.

The printing process also depends on the device, materials, and intended function of the object. In binder jetting, the printer uses a binding agent layer by layer. In filament based systems, a heated nozzle extrudes material while following the G code path. In resin based systems, UV light cures liquid resin one layer at a time. In each case, the underlying 3D printing file must represent the object precisely to avoid failure or inconsistencies. It acts as both a structural guide and a roadmap for all machine operations.

What role does mesh quality play in the success of a 3D printing file?

Mesh quality determines how well a 3D model transitions into physical form. A mesh made of evenly distributed triangles allows the slicer to calculate smooth curves and sharp edges. If the triangles are stretched or uneven, the printed object may display visible artifacts. Thick surfaces, solid interiors, and clean boundaries help guarantee sturdy prints. Thin walls or irregular geometry can cause fragile areas where the material cannot adhere correctly.

When users upload models into RealityMAX, the viewer reveals mesh resolution clearly, making it easier to spot errors that would go unnoticed in a traditional modeling interface. A mesh that appears smooth in a workstation might show hidden distortions when viewed through a neutral platform. This step allows designers to refine their model before printing, reducing wasted time and materials. Fixing mesh issues early improves consistency and ensures that the 3D printing file performs as expected.

Mesh cleanup is also important when converting files. An OBJ file containing dense textures or sculpted details may become unnecessarily large or complex. Simplifying the mesh before exporting the STL format can make the file more efficient without losing essential detail. Adjusting the triangle count, optimizing surface flow, and repairing non manifold edges help produce a clean 3D printing file that behaves predictably in any slicing environment.

Why does file resolution matter in additive manufacturing?

File resolution affects both visual quality and structural stability. A high resolution STL file uses more triangles, capturing subtle curves and fine features. This leads to smoother surfaces in the printed object but increases slicing time and memory usage. A low resolution STL file reduces complexity but can introduce faceting, where curved surfaces appear as visible segments. Finding the right balance between resolution and efficiency depends on the project.

For functional parts used in engineering or CNC machining workflows, resolution influences precision. Misrepresenting a curve or misplacing a vertex can alter the performance of a component. In artistic objects used for spooky season decorations, prototypes, or visual displays, resolution shapes the realism and texture quality of the final piece. In both cases, the resolution of the 3D printing file guides the machine in forming consistent layers.

RealityMAX helps users preview models at different scales, revealing how resolution choices impact the visible shape. A model that looks smooth in a small digital window may appear segmented when rotated or magnified. Adjusting resolution before exporting ensures that the 3D printing file captures the desired appearance without overwhelming the slicing software. The right resolution also helps manage file size, making it easier to upload, download, share, or archive models across platforms.

How do material choices influence the structure of the 3D printing file?

Materials shape how the file should be prepared. Different printing technologies require different structural conditions. Flexible materials need thicker walls to maintain shape. Rigid materials allow thinner structures but may require internal support depending on the geometry. Resin based systems handle detail differently from filament based systems. A 3D printing file must account for these material properties before slicing.

Some materials expand slightly during printing, while others shrink. A model prepared for injection molding may require adjustments to compensate for these changes. Additive manufacturing often allows more freedom, yet the geometry still needs stability. Internal cavities, transitions, and thickness variations must align with the capabilities of the chosen material. Preparing the 3D printing file with this in mind reduces print failures and helps achieve reliable results.

RealityMAX does not prescribe a specific material, but it gives users a clear view of their geometry so they can make informed decisions. Visualizing the model in neutral lighting reveals how different surfaces might respond to stress or heat. Teams can annotate the scene, discuss material implications, and refine decisions collaboratively. The 3D printing file becomes the starting point for all material related considerations.

How can users identify compatibility issues before slicing?

Compatibility issues typically arise when the 3D printing file contains geometry that does not align with machine constraints. Thin walls, inverted normals, intersecting faces, or open edges can cause failure during slicing. A user might not notice these issues while working in CAD or sculpting software. When the file moves into a new environment, the problems emerge.

Uploading the model to RealityMAX helps reveal these incompatibilities early. The viewer provides real scale visualization, making it easier to detect distortions or proportion issues. Measuring tools and annotations allow users to examine thickness, angles, and details. Once problems are identified, they can return to the modeling software and refine the geometry before exporting again. By iterating visually and structurally, designers improve the reliability of the 3D printing file.

Some printers also impose maximum file sizes or triangle counts. If the file is too heavy, the slicer may struggle or crash. Simplifying the mesh, removing hidden geometry, or reducing resolution helps avoid these workflow disruptions. Ensuring compatibility before slicing saves time, reduces frustration, and keeps the process efficient.

How can creators convert models into a reliable 3D printing file?

Many creators begin with models that are not originally intended for printing. Digital sculpts, CAD sketches, artistic 3D forms, and concept models need to be adapted before slicing. Converting them into a valid 3D printing file involves cleaning the mesh, choosing the appropriate format, and ensuring watertight geometry. Software tools that specialize in conversion help bridge this gap, yet creators must remain aware of the structural rules required for printing.

When converting OBJ files to STL format, the goal is to strip away texture data and focus on the geometry. Checking surface continuity, ensuring consistent normals, and eliminating overlapping faces are essential steps. Smoothing or remeshing areas that contain stretched polygons also helps generate a cleaner result. Exporting at the correct scale prevents mistakes during slicing and ensures that the printed model sizes correctly.

RealityMAX supports this workflow by offering an environment where creators can test their models visually. After conversion, users can revisit their models in the viewer to confirm that the export aligned with expectations. The ability to update, upload, and refine quickly improves the overall workflow. Once the conversion is complete, the 3D printing file becomes the foundation for the next stages of production.

How does collaborative review improve the quality of a 3D printing file?

Collaboration plays a significant role in modern workflows. Engineers, designers, artists, and manufacturers often contribute to the same project. A 3D printing file must reflect decisions made across teams. Without a shared environment, miscommunication becomes likely. Details such as surface thickness, orientation, or assembly tolerance require collective agreement.

RealityMAX allows multiple users to view and analyze the model in the same space. Teams can identify areas that may need additional support, make suggestions about scale adjustments, or point out design opportunities. These insights improve the structural clarity of the 3D printing file. When the final model reaches the printer, the combined knowledge of the team reduces uncertainty and improves the chance of successful fabrication.

Commenting features, annotations, and shared workspaces help teams maintain a single source of truth. Instead of passing files manually or relying on screenshots, users can interact with a real 3D viewer. This reduces errors introduced by misinterpretation. The collaborative process turns the 3D printing file into a more robust and thoroughly inspected object.

What limitations should users be aware of when preparing a 3D printing file?

Even with modern software and intuitive platforms, certain limitations remain inherent to the medium. A 3D printing file cannot overcome physical material constraints. A shape that appears stable in digital space may collapse when printed if the structural support is insufficient. Thin features that look acceptable in a high resolution model may break under the weight of the upper layers.

Another limitation involves resolution. Increasing the triangle count improves precision but may create heavy files that exceed the memory capacity of slicing tools. A model with excessive detail may slow down the machine or produce errors during processing. Designers must balance their artistic vision with the mechanical reality of the printer.

Technical limitations also arise from manufacturing methods. Laser cutting depends on clear contour lines. CNC machining requires toolpath logic that aligns with the geometry. Binder jetting demands attention to wall thickness and internal support. In each case, the 3D printing file must respect the constraints of the chosen process. This requires knowledge of both digital modeling and physical production.

How can RealityMAX help users visualize and refine 3D printing files?

RealityMAX offers a browser based environment where creators can upload 3D models, inspect them from every angle, adjust materials for visualization, and share them with collaborators. It removes the need for downloads or installations and provides instantaneous access across devices. Whether users work on macOS, Windows, Linux, or mobile devices, they can interact with their models in real time.

The platform highlights structural details that might influence the printing outcome. Viewing the model with neutral lighting reveals subtle imperfections. Rotating the object quickly helps users analyze proportion. Annotations allow teams to mark problematic areas or discuss improvements. This visual clarity enhances the preparation of the 3D printing file before exporting it to slicing software.

RealityMAX also supports workflows where users need to compare multiple formats. A designer might upload an OBJ file with textures, review the appearance, then export an STL version for printing. The ability to store and review different versions in the same workspace helps maintain consistency and organization. The platform becomes a bridge between ideation, visualization, and production.

How do creators ensure reliability across different printers and technologies?

Reliability depends on consistent geometry, appropriate resolution, and correct format selection. A 3D printing file that performs well on one machine may behave differently on another if the file is not normalized. Printers vary in nozzle size, build volume, material capabilities, and firmware expectations. Standardizing the file helps reduce unexpected behavior across devices.

STL files provide this standardization. Their universal support allows creators to share models across manufacturers without worrying about proprietary structures. OBJ files add versatility by providing additional information for visualization, which is useful when reviewing models on platforms like RealityMAX. Ensuring that units, scale, and orientation remain consistent across exports reduces risk and maintains reliable output.

Testing is another important factor. Printing small sections or simplified versions of the model allows creators to verify performance before committing to the full print. Insights gained from these tests inform the preparation of the 3D printing file. By adjusting angles, supports, or internal thickness, designers can optimize for stability and accuracy.

How does geometry complexity affect the behavior of the 3D printing file?

Complex geometry challenges both the slicing software and the machine. Highly detailed surfaces may require more processing power and time. Intricate patterns or internal cavities can confuse the slicer if the geometry is not clean. Overly dense meshes make uploads slower and consume unnecessary memory.

Simplification tools help balance detail and performance. Reducing triangle density in areas where it does not influence shape preserves visual quality while improving file efficiency. Converting sculpted forms into clean topology enhances the behavior of the 3D printing file under slicing conditions. Rebuilding problematic sections ensures that machines interpret them correctly.

RealityMAX offers a clear visualization of geometric density. A model that appears smooth in its original software may reveal unnecessary complexity when examined in a neutral environment. Identifying these areas allows creators to restructure their mesh accordingly. This optimization becomes even more important when users manage large collections of models or produce objects for commercial purposes.

How do users maintain accuracy when converting between file formats?

Converting between formats always introduces risk. Some formats approximate geometry differently. Others handle orientation, smoothing, or precision in unique ways. When converting an OBJ file to an STL file, users must verify that the exported model maintains scale, thickness, and geometric integrity.

Checking normals, sealing holes, and verifying manifold geometry helps maintain accuracy. Comparing the original file and the exported version side by side in RealityMAX reveals discrepancies quickly. If the exported STL file displays distortions or missing sections, users can adjust export settings or refine the mesh before attempting another conversion.

Maintaining accuracy also involves understanding the strengths of each format. OBJ files carry additional information that may not transfer to STL files. While the visual differences might not matter for printing, they may affect how teams interpret the model during planning stages. Keeping both versions organized and labeling them accurately ensures that the workflow remains structured.

How does annotation improve communication around a 3D printing file?

Annotation turns a static file into a communication tool. When teams discuss a model, specific details matter. A collaborator might need to highlight a sharp edge, a thin surface, or a potential failure point. Without annotations, these comments might get lost in messaging threads or become unclear.

RealityMAX incorporates annotations directly into the 3D environment. Users can mark areas with comments and attach insights to specific parts of the geometry. Anyone reviewing the model can follow the annotations, respond, or implement changes. This interactive approach keeps the 3D printing file connected to the collaboration process rather than treating it as a separate step.

Annotations also help maintain a record of decisions. When printing complex assemblies, tracking the evolution of the model helps future team members understand why certain choices were made. The annotations remain integrated into the workspace, supporting transparency and continuity across the entire project lifecycle.

What are the most common errors users face when preparing a 3D printing file?

One of the most frequent problems is non manifold geometry. When edges or vertices do not connect correctly, the slicer becomes confused about what is inside and what is outside. Another common issue involves inverted normals, which flip the direction of the surface. This disrupts layer calculations and causes incorrect printing behavior.

Holes in the mesh also create difficulty. Even a small gap can prevent slicing from generating a stable internal structure. Overlapping faces or internal surfaces add further complications. The slicer may attempt to interpret these forms as separate objects or generate irregular toolpaths.

Scale errors are another challenge. A model created in millimeters might import as meters in the slicer if the units do not match. This results in parts appearing far too large or too small. Checking scale during export or reviewing the model in RealityMAX prevents this confusion.

How do creators monitor printability before manufacturing?

Printability describes how well the digital model translates into physical form. Certain forms might be visually appealing but structurally unlikely to succeed without modification. Overhangs, thin bridges, and unsupported angles all influence printability. Tools that analyze the geometry help users identify these areas before committing to the full print.

Examining the model in RealityMAX at different angles reveals potential failure zones. If a part seems unstable or too intricate, the creator can adjust the geometry or orient the object differently. Using preview renders within the slicing software also provides insight into how the layers will form. All these steps serve to refine the 3D printing file.

Printability also depends on machine settings. A design might be printable on one device but not another. Understanding nozzle size, build volume, and extruder precision helps creators tailor the 3D printing file to the appropriate hardware. Maintaining awareness of these limitations prevents costly mistakes.

How does orientation affect the performance of the 3D printing file?

Orientation changes how the printer approaches the build process. When an object is rotated, the slicer recalculates supports, infill structures, and layer lines. Certain orientations reduce the need for supports, while others increase stability during printing. Orientation influences strength, aesthetics, and production time.

Choosing the right orientation helps improve the durability of functional parts. Aligning stress bearing surfaces with the direction of filament extrusion increases resistance to fracture. For visual pieces like spooky season props or display models, orientation influences surface quality. Surfaces printed vertically may show fewer layer lines compared to horizontal sections.

RealityMAX assists creators by offering a flexible 3D viewer where they can test different orientations visually. Once a preferred orientation is selected, creators can export the 3D printing file and prepare it for slicing. Consistency in orientation across different stages ensures that the results match expectations.

How can creators detect thickness issues before printing?

Wall thickness plays a crucial role in printability and structural stability. Thin walls may collapse or fail to adhere during printing. Thick walls add unnecessary weight and consume more material. Determining the correct thickness depends on the chosen technology, material, and use case.

When examining the model in RealityMAX, creators can zoom closely into problem areas and assess whether surfaces appear balanced. If a surface looks too sharp or narrow, it may require adjustment. CAD software often includes thickness analysis tools that highlight critical areas, helping designers modify their geometry accordingly.

Thickness problems often occur in models imported from sculpting software. These programs allow artists to create thin or delicate structures that appear stable visually but lack support internally. Before exporting the STL format, creators can add reinforcements, smooth boundaries, or combine multiple layers to improve consistency.

Why is watertight geometry essential for every 3D printing file?

Watertight geometry ensures that the mesh contains no holes or gaps. The slicer must interpret a closed volume for printing. If the surfaces do not connect properly, the software cannot determine which areas represent solid material. This confusion leads to unpredictable toolpaths or failed prints.

Watertight geometry also strengthens the printed object. A model with internal gaps may produce weak sections where the material does not adhere properly. For structural parts, these weaknesses reduce reliability. Even decorative pieces benefit from watertight design because the final surface appears smoother and more consistent.

Testing for watertight geometry involves visual inspection and automated analysis. Viewing the model inside RealityMAX highlights visible gaps. Many modeling tools include repair functions that seal holes or merge vertices. After correction, exporting a fresh 3D printing file ensures that the slicer receives a clean, consistent model.

How do creators manage collections of 3D printing files for large projects?

Managing large collections of models requires organization. Creators working on multi part assemblies, product lines, or seasonal projects like spooky season decorations often accumulate dozens or hundreds of files. Keeping track of versions, formats, and modifications becomes essential.

RealityMAX helps by offering cloud based organization where users can store multiple models in dedicated workspaces. They can label files, compare versions, and collaborate with teammates. This structure prevents confusion when switching between STL, OBJ, and other formats.

Maintaining a consistent naming system also improves workflow. Including version numbers or descriptive labels ensures that collaborators always reference the correct 3D printing file. When users return to the project months later, they can identify the correct file without sorting through outdated or duplicate versions.

What future developments can improve the use of 3D printing files?

The future of 3D printing files includes smarter formats, improved compression, better metadata handling, and deeper integration with cloud based workflows. As additive manufacturing evolves, new formats may emerge that combine the simplicity of STL files with additional information like material preferences, print instructions, or structural annotations.

Integration with platforms like RealityMAX will continue to expand. Users may soon be able to simulate printing outcomes directly within the viewer. Advanced analysis tools could predict deformation, estimate costs, or evaluate mechanical stress. Printed objects could become part of a broader ecosystem where creators move seamlessly from design to fabrication.

File formats may also adapt to emerging printing technologies. As printers support more materials, higher resolution, and greater build volumes, 3D printing files will need to store more information. Balancing file size with functionality will remain an ongoing challenge. Despite these changes, the principles of clean geometry, watertightness, and accurate representation will continue to guide the creation of high quality 3D printing files.

Why does the 3D printing file remain the heart of every digital fabrication project?

Every fabrication method depends on clear instructions. Without a proper 3D printing file, even the most advanced machine cannot produce a reliable object. This file acts as the bridge between imagination and reality. It carries the structural logic, the geometry, and the language that machines require. It connects designers, engineers, manufacturers, and hobbyists in a common workflow.

RealityMAX enhances this connection by offering a platform where creators can visualize, refine, and share models effortlessly. It supports users across disciplines and skill levels. The clarity it provides helps ensure that the 3D printing file performs exactly as intended. When creators understand how the file behaves and how machines interpret it, they improve not only their prints but their entire creative process.

As digital fabrication continues to expand, the 3D printing file will remain central to innovation. It embodies the possibilities of the modern world, where objects move from code to reality with precision and creativity. With the right tools, the right preparation, and the right understanding, any idea has the potential to take shape layer by layer.